F.A.Q for Raised Floor Plenum Testing

Raised floor plenum testing demonstrates the air tightness of the space below the raised access floors. Achieving air tightness in plenums is critical in achieving efficient air handling within buildings. Once the plenum has been constructed, an air tightness test to BG65/2016 must be undertaken to ensure the plenum meets design specifications.

Measuring the air leakage from a floor plenum, which is a void between a building’s floor structure and a raised access floor, used for distributing conditioned air to the spaces above. It is important to ensure that the floor plenum is airtight, as air leakage can cause energy inefficiency and discomfort to the occupants.

What’s the cost of a Raised Floor Plenum Test?

The cost of a floor plenum test may vary depending on the size, complexity, multiples, and location of the plenum, as well as the quality of the testing company and the standards followed.

However, the cost of floor plenum test in UK ranges from £500 to £750 in the UK and £850 to £1000 in London. This does not include the cost of any air leakage surveys using smoke and thermal imaging, as well as any remedial work that may be required to seal the plenum and reduce air leakage. For a more accurate estimate, please contact us at info@airpressuretesting.net and request a quote.

What’s the duration of a Raised Floor Plenum Test?

The duration of a floor plenum test may depend on several factors, such as the size and shape of the plenum, the number and location of the test points i.e., are they in different buildings, the equipment and method used. However, in our experience the average duration of a floor plenum test is about 2 to 4 hours per floor plenum – this doesn’t include the time required for any preparatory or remedial work sealing works that may be needed before or after the test.

What happens if I fail the floor plenum test?

If you fail the raised floor plenum test, it means that your floor plenum is not airtight enough and may cause problems with the air distribution and energy efficiency of your building.

To try and attain a pass for our client on the day, we can carry out a smoke and thermal imaging survey to highlight air leakage paths through fabric (walls, floor, and floor tiles) and issue a report for reference during the remedial sealing works. In many cases if the air leakage can be found and is quite easy to seal, the remedial works can be carried out during the test visit.

What result do I need to pass a raised floor plenum test

According to the **BG65/2016** guide on floor plenum airtightness, the worst acceptable criteria for air leakage from floor plenums are:

• Plenum leakage: no more than 0.7 litres/s/m2 at a pressure of 50Pa – this is the air leakage through the plenum envelope into adjacent spaces via the walls, floors, cavities, internal columns, risers, service penetrations, heating trenches or other zones.

• Raised access floor leakage: no more than 1 litre/s/m2 at a pressure of 50Pa. This is the uncontrolled air leakage into conditioned zones, such as through joints in the raised access floor or between the raised access floor and walls junction.

These criteria are recommended to ensure energy efficiency and comfort for the users of the building. More stringent air leakage specifications may be required for critical environments, such as data.

Common sources of air leakage in floor plenums are:

In our experience, some of the common sources of air leakage in floor plenums are:

1. Service penetrations – that run through the access floor, walls and subfloor, such as cable bundles, cable trays, pipes, fire barriers, etc.

2. Cable trunking – that is not internally sealed within the trunking void.

3. Grilles and diffusers – gaps around grills and diffusers that are not sealed or gasketed.

4. Poorly installed masonry – walls etc. that has not been jointed and/or has missing masonry resulting in gaps and cracks.

5. Service Risers – that are not properly sealed for plenums or ducting.

6. Plasterboard – installed on studs that has not been properly sealed at board edges and the ends below the raised floor level.

7. Junction Joints – between tiles or between tiles and walls/columns that are not sealed or gasketed.

Excess air leakage in floor plenums can cause energy inefficiency and discomfort to the occupants, as well as affect the performance of the floor-mounted diffusers or grilles. Therefore, it is important to design, install and test the floor plenums for airtightness, following the standards and guidelines provided by BG65/2016.

How to prepare for a raised floor plenum test

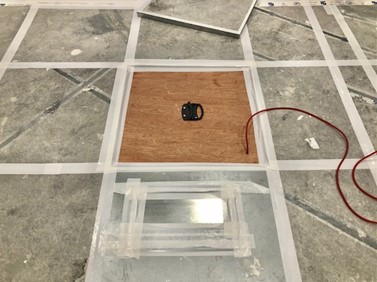

There are many things to consider when preparing your raised floor plenum for the air tightness test. for instance, before installing the floor tiles, we recommend that careful checks are undertaken to all areas of the floor plenum, the main areas to check and seal are the wall/floor junctions, wall/raised floor junction, columns/floor and raised floor junctions, ductwork, and cable trays.

During the installation of ductwork/cable trays, it is common to miss out the sealing beneath the duct/tray where it penetrates the wall, and this is then very difficult to seal at a later stage. When planning the work with the contractors, we’d recommend highlighting this area and installing an airtight seal beneath the duct.

Also, all masonry, fireboard and plasterboard should be carefully checked to ensure that all joints are fully sealed, and no damage has been caused by the later inclusion of services.

Also, prior to the taping of the floor, ensure that all ductwork openings and/or the air handling units are fully sealed. To avoid any areas have not been missed, check the drawings to identify where these are in the plenum.

Also, prior to the installation of the tape, ensure that the raised floor tiles and surrounding walls etc. have been carefully cleaned, otherwise the tape will come off during the plenum test whilst under pressurisation. It would also be worth using a high-tack tape to ensure it stays in place throughout the plenum test.

If you would like to know how to prepare for your floor plenum test, please click on the following link how to pass a floor plenum test.

Why Choose us APT for your Raised Floor Plenum Test!

Our team of floor plenum test engineers provide a high-quality testing service for commercial properties throughout London and the Southeast.

We use the latest Retrotec testing equipment that allows us to test all sizes of access floors, to ensure your floor plenum meets the requirements of BG65/2016.

We provide the following as part our professional testing service:

• 20 years of air testing design and testing experience

• UKAS accredited testing laboratory

• ATTMA Level 2 certified

• The latest UKAS calibrated equipment

• Smoke and thermal imaging air leakage detection service

Contact us today to learn more about our floor plenum testing services and how we can help you achieve a test pass for you project! For more information call APT today on: 0777 5623464 or email us at: info@airpressuretesting.net